BLOW MOULDING TECHNOLOGY

- Home

- BLOW MOULDING TECHNOLOGY

Innovations & Inventions

Blow Moulding Technology

Resinex India Water Tanks are manufactured using Blow Moulding Technology. The blow moulding process beings with the melting down the plastic and forming in into a parison is a tube-like piece of plastic with a hole in one end through which compressed air can pass. The parisons is then clamped into a mould and air is blown into it. The air pressure then pushes the plastic out to match the mould. Once the plastic has cooled and hardened the mould opens up and part is ejected.

Blow moulding is a relible manufacturing option that allows for very precise possibilities product. the process also has a number of inherent design strengths, such as customer wall thickness and strong outside corners. for additional strength, ribs from an integral part of design.

PROBLEMS IN BLOW MOULD TANK

Unreliable /Untested TechnologyHence breakage

Not long life/Durability

LightWeight

Unrated /NotApproved

SOLUTIONS OUR PRODUCTS OFFERS

- Power of 3M

- Lab Testing

- Approval certificate

- German Technology Based Wall Thickness Controller

Various Layers of our Blow Mould Products

ESTEEM 3 LAYER

ELITE 4 LAYER

EBONY 5 LAYER

KANAK 3 LAYER

KANAK 5 LAYER

Power of 3m

MACHINE (मशी न)

It is a revolutionary from of technology. Although, initial machines between 2008 to 2013 had limitation of ascertaining certain parameters like melt temperatures. Post 2013 corrections were made with introduction of 4 layer blow mould machines. And again in 2017 improved 5 layer blow mould machines has resulted in stronger, heavier and robust water tanks. In 5 layer machines, cooling down of finished products has been made slow to reduce building up of stress in the final water tank.

It is just a myth that blow mould water tanks are weaker than the rotational mould tank. In fact, sophistication of blow molding technology has allowed engineers to try and create a variety of application and designs that need precision. Which resulted to multiple interesting uses. Products created using this technology include fuel tanks in cars (High pressure and heat resistant, Blue drum chemical tanks(excellent strength and life to store precious chemicals). seat support for vehicles. toy wheels. This technology has always been moving forward with the purpose of becoming universally used with plastic production.

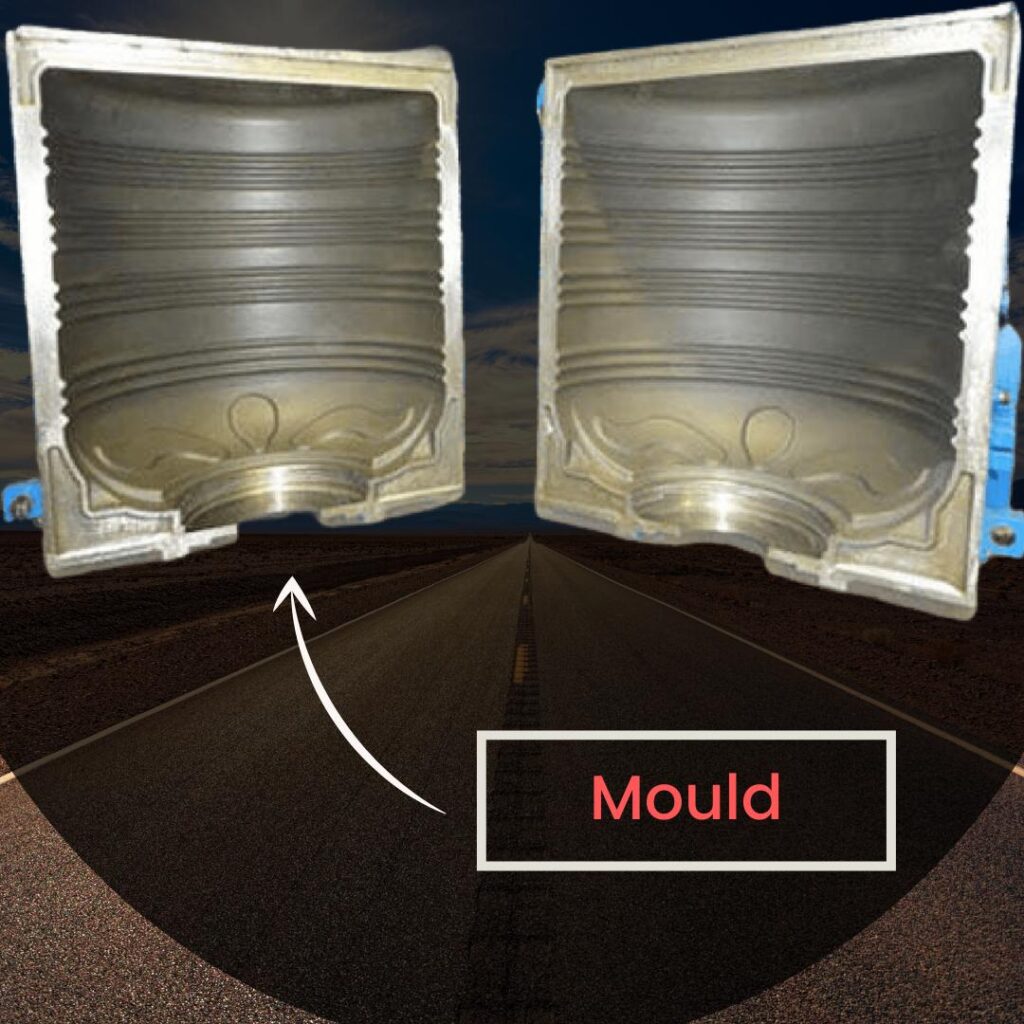

Mould (मो ल्ड)

Since, mould design is an important part of the manufacturing process, it is now more scientific then ever before.

Resinex has carefully taken care of every details of fundamentals of blow mould technology and characteristic of material flow to ensure a superior quality of final product is manufactured its production facility.

Another advantage of Resinex mould, ensures overlapping beneath the base of the tank parting line. Which makes those areas even more stronger.

Our mould design offers hooks for ease of handling and transportaion. Hook also reduces chances of accidental damage

during lifting of the tank.

Material (मैटेरि यल)

Resinex water tanks are only manufactured from 100% pure virgin high density polyethylene plastic granules. Resinex tanks are food grade and are safe for water storage.

Resinex uses high density polyethylene blow having appropriate swell ratio to diminish stress building during manufacturing process.

We are one of the very few companies of India who, irrespective of the pricing implications, has opted to use globally acclaimed special imported plastomer to make water tank more durable and resistant to sun. Further we use antioxidants and ultraviolet combination to enhance environmental stress and cracking resistance ability of the water tank.

About Us

We are a group of companies into hardware business for the last 80 years. In 1988, we were incorporated as one of the largest distributors of products of Kisan Mouldings Limited, Mumbai in India.

Quick Links

Contact Us

- +91 9305837105

- mail@resinexindia.com

- 84/54 Singh Engineering Compound, G.T. Road